Implement Best Practice Motor Management

Bearing Currents, EDM and Bearing Fluting

3Phi Reliability are the Go To specialists in solving Bearing problems related to Inverter emissions.

Contact us if you have had repeat failures that are Inverter Driven, we permanently solve these Bearing failures and teach your technical staff how to set a standard to stop on going problems.

We have supported multiple clients globally via AR Glasses / Video Link, cost effective solution for your technical staff.

How long does it take to Implement Electrical Preventative Maintenance

Typically a three day on site coaching visit is enough to

provide your technicians with new skills and to gain some initial

improvements.

Learn how to:

Terminate a motor and get the resistance as low as possible.

Set a tightness Standard with Torque Drivers

Identify crimping problems, use of the correct Crimping tool

Measure Variable Speed Drive or Variable Frequency Drive emissions that cause Bearing Attack & Insulation Failure

Compliment Thermography with Resistance Testing to find hidden defects.

Meet Regulatory Requirements of three year Scheduled Maintenance for your Electrical Preventative Maintenance program.

How to implement a Sustainable Electrical Preventative Maintenance Program including Electric Motor Testing.

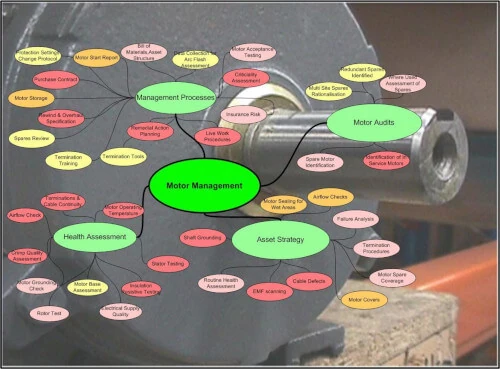

Best Practice Motor Management has four elements

1. Know what you have in your Facility, and Motor Spares

2. Purchase for Reliability, 5S your Motor Store to minimize Response Time

3. Health Assessments of your Electrical Assets with Maintenance Checklists

& Motor Circuit Analysis. Identify which Motor Windings are at risk.

4.Total Preventative Maintenance Plan that drives down failure rates

A Holistic Approach to FMECA RCM Analysis

Electric Motor Testing compliments Vibration Analysis, it provides answers to 100hz (120hz) defects.

3Phi Reliability are specialists in solving Bearing Fluting and Drive Defects. Improving Lubrication practices, Optimizing "ON CONDITION" Schedules.

3Phi Reliability Strive to provide same day support for Clients and enquiries.

Example of Energy Savings & Reliability Gain

Example: 3500 GBP per annum in Electrical losses, Identified and Fixed

Defects found: Drive Terminations,

Crimping of Lugs,

Loose Connections,

Poor Termination Arrangement,

Crimp Lug damage

Financial Justification of Motor Defects. Financial Justification Example

Motor Audit

An onsite collection of motor assets using a mobile database App and data presented in a CSV format for your CMMS upload.

Both In Service and Spares are identified allowing an assessment based on your criticality and business needs. This assessment shows the "Where Used" spares coverage, and any risk of incorrect spare. Motor Audits across multiple sites can identify where spares should be stored, redundant spares, and rationalization opportunities. Collected details include shaft details, name plate data, mounting allowing for variants and database includes photographs for easy identification. A motor audit is recommended for the first step in your Best Practice Motor Management program.

Motor Health Assessments

Identify the reliability status of your electric motor assets using Motor Circuit Analysis. This method tests the entire system from the distribution board and will identify potential energy savings. This assessment is combined with continuity testing, visual inspection of terminations, and EMF (electromagneticfreq) of induced sources which is common in bearing fluting attack. The methods in the Motor Health Assessment are consistent with the IEEE 1415 -2006 "Guide for Induction Machinery Maintenance Testing and Failure Analysis".

Identify the reliability status of your electric motor assets using Motor Circuit Analysis. This method tests the entire system from the distribution board and will identify potential energy savings. This assessment is combined with continuity testing, visual inspection of terminations, and EMF (electromagneticfreq) of induced sources which is common in bearing fluting attack. The methods in the Motor Health Assessment are consistent with the IEEE 1415 -2006 "Guide for Induction Machinery Maintenance Testing and Failure Analysis".

Asset Strategies

Use our experience to workshop Asset Strategies taylored for your enterprise. A FMECA (Failure Modes, Effects & Critically Analysis) focused on Electric Motor Assets.

Proven Strategies have made immediate returns and gained Reliability improvements many times the initial investment.

Our workshop training gives an insight into how and why motors fail that are common to industry.

Management Processes

Reliability needs to be supported by a Purchsase & Overhaul Specification, installation guidelines, Correct Storage & Identification and Acceptance testing. These processes reduce response time in the event of a failure. Management Processes are essential ensure the asset you install is "FIT FOR USE". Use our experience in failure analysis to make continous improvements.

5S your Motor Store to reduce response time.

Qu’est-ce que les meilleures pratiques de gestion des moteurs électriques?

quest-cequelesmeilleures0apratiquesdegestiondesmoteurs0alectriques.pdf

DownloadMotor Spares purpose is to reduce response time, How do you rate your Store?

Fit for Use Motor Spares, tested and 5S.

5S your Motor Store to Reduce response time

Ask for a quote

Contact Us for a Quote (Pick options from the motor management diagram) to make a taylored solution for your needs, or just need advice to implement your Reliability programme.

3Phi Reliability offer a Service Kit for Implementation of your Electric Motor Management Programme on a cost effective monthly basis globally.